Discover OSMOS

Proposal

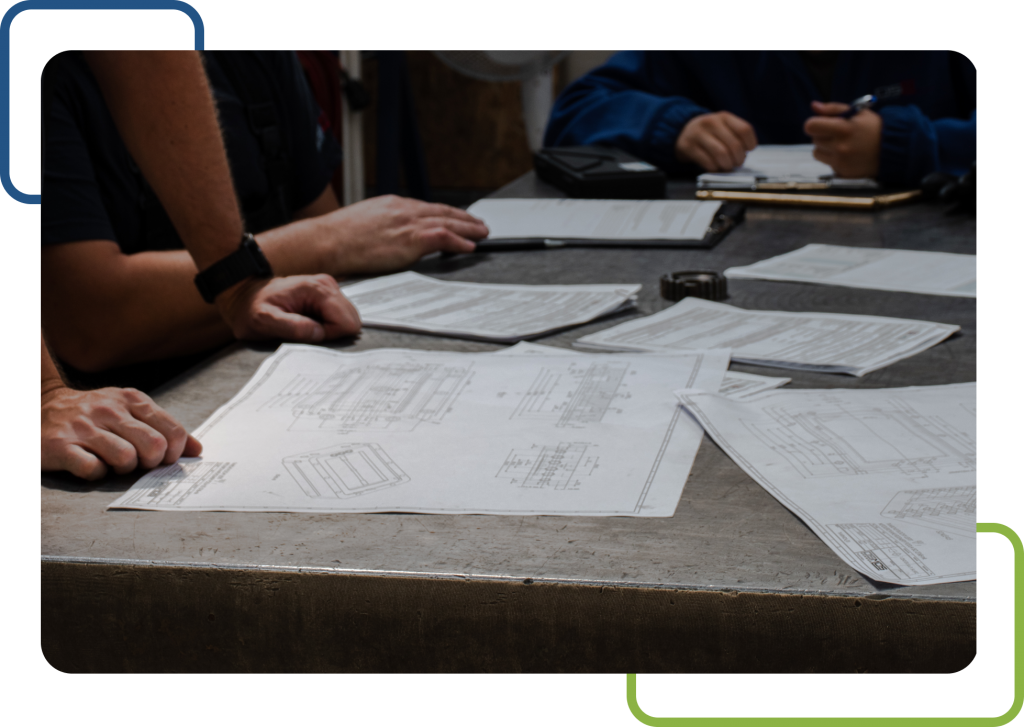

Tool shop

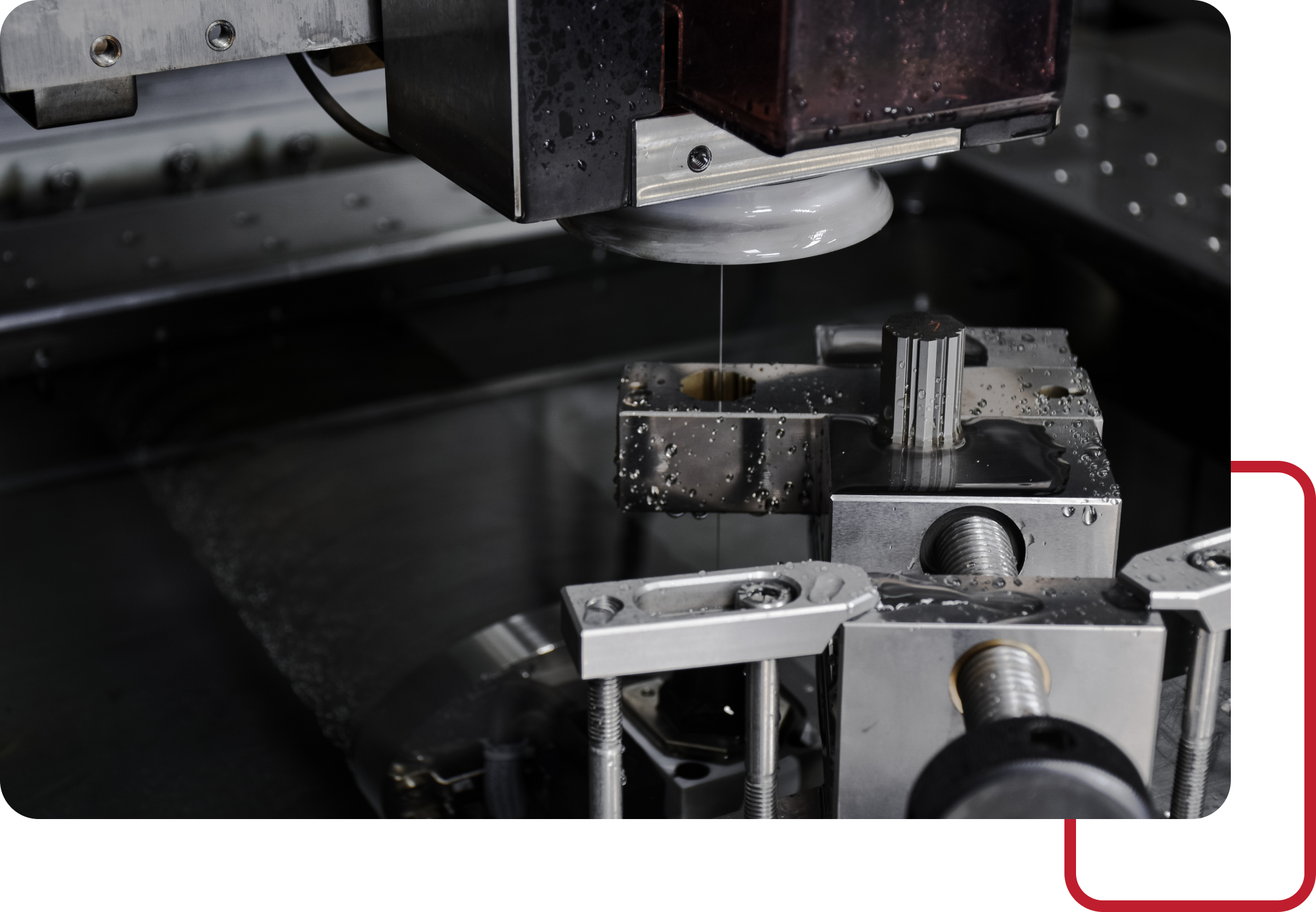

Plastic pressing

Software

PROPOSAL

PROPOSAL

Tool shop

Tool shop

PRESS

PRESS

Software

SOFTWARE

How it works in practice How it works in practice

Contact us

Need to know more? Do not hesitate to contact us by email or this form.

- Software

- Tool shop

- Plastic pressing

Who we are?

I consider the biggest benefit of PdC in our company to be: – Clear book of orders (through projects), production orders and products in different states – Possibility to save drawings and other info for calculations, projects – Support for «standardization» for the calculation of bids and at the same time create basis for production processes – Purchasing process clearly integrated into the production process – Possibility to move production into cooperation if we do not manage to produce it ourselves – Time registration associated with the production process and back-calculation (allows measuring the “efficiency” of an individual employee and subsequent remuneration)

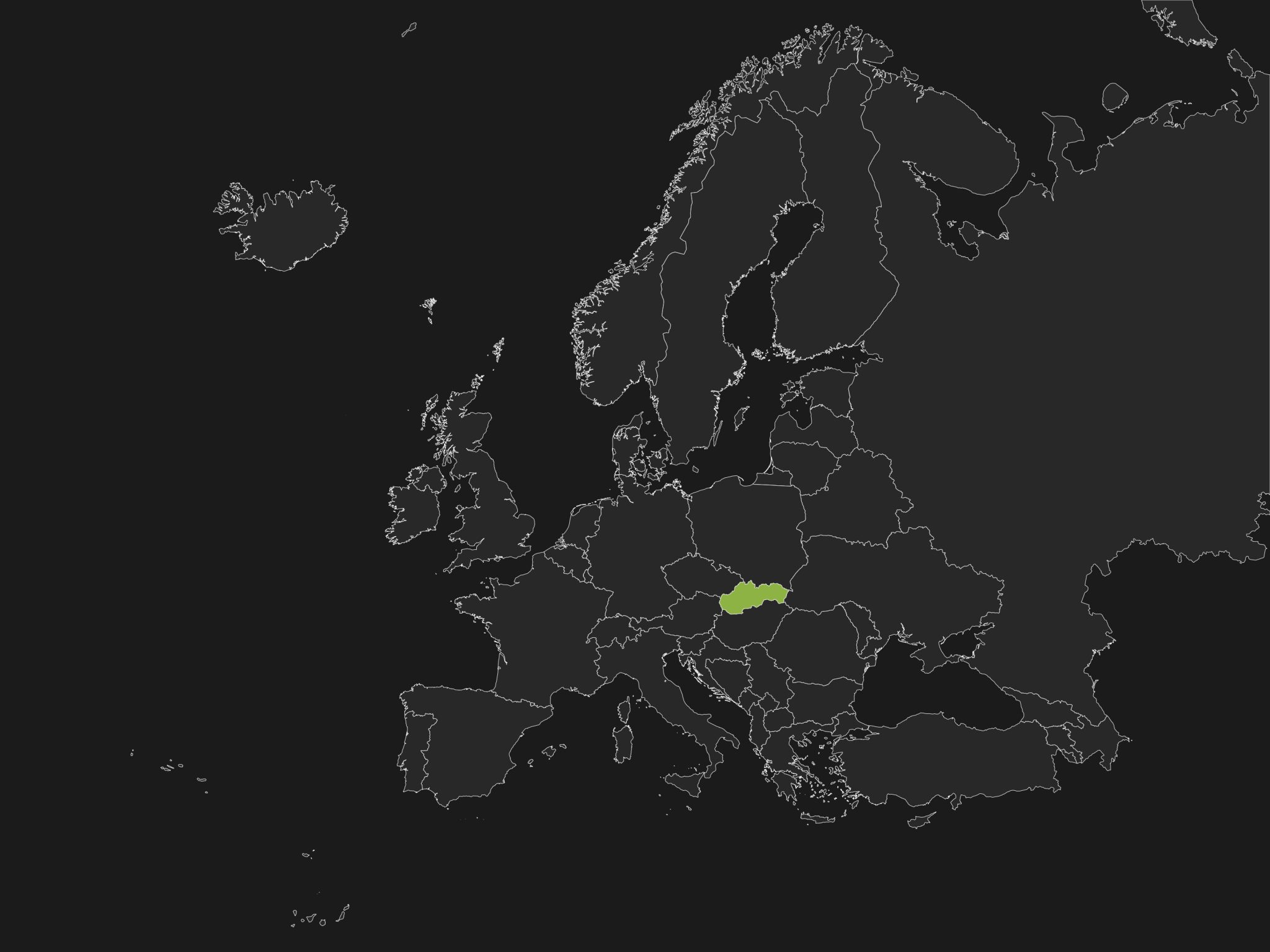

We ship 90% of our production to the entire EU

Slovakia

Germany

Denmark

Czech Republic